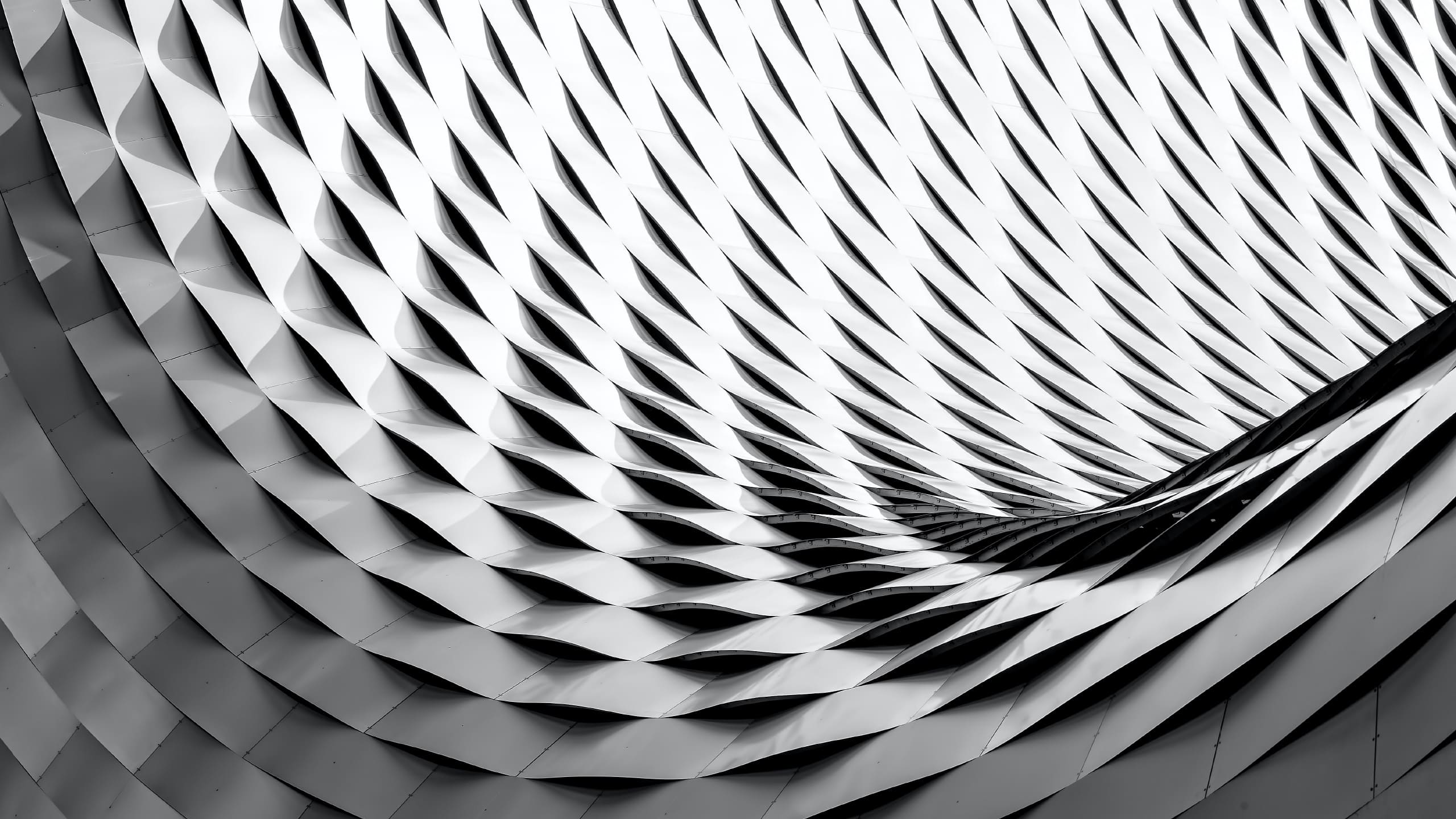

Our Differentiation

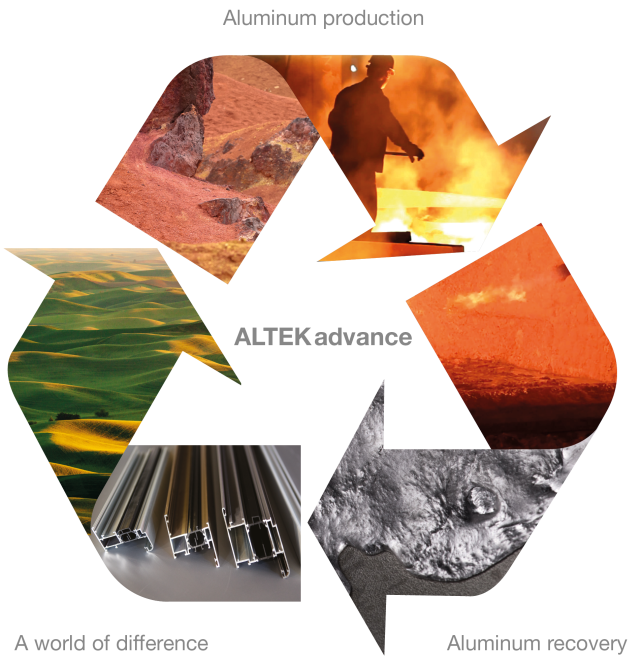

We have continued to push the boundaries and look at our industry with fresh eyes, resulting in new and advanced industry 4.0 solutions across the entire casthouse that are transforming the aluminum industry. Learn about ALTEKAdvance, the four pillars of our brand.

Leading-edge solutions to age-old problems

We challenge conventional thinking and continuously look for better ways to do things, creating new concepts and products that utilize the latest technology to shape the future of our industry.

End-to-end Dross Solutions

On-site, scalable and sustainable. Ensuring nothing goes to waste.

Furnace Circulation

World-leading, air-cooled technology for your stirring requirements.

Casting Solutions

Long-lasting and durable alloy castings for improved productivity.

ALTEK, world leader in developing solutions for sustainable aluminum production

Many think our Total Dross Management is alchemy, but it is only the result of Altek advance thinking. Our system drastically reduces atmospheric pollution, creates no waste and is totally green.

ALTEK installations supply the aluminum industry world-wide.

Explore new and exciting possibilities with ALTEK

Fill out the form and our sales team will reach out to start a conversation about how ALTEK can help your business save money.

For urgent inquiries, email us at sales@altek-al.com