Mould-breaking Technology

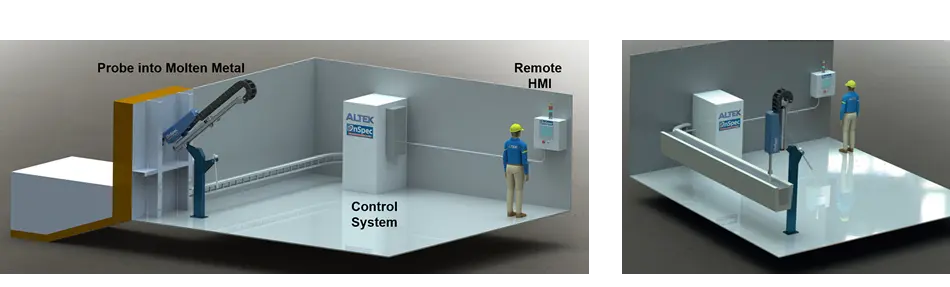

Metal quality is a critical and essential part of the finished product and the control of this as an integral part of the production process. OnSpec™ is a Laser Induced Breakdown Spectroscopy allowing real-time process control to ensure faster response times within the aluminium making process.

OnSpec™ is a LIBS (Laser Induced Breakdown Spectroscopy) technology which allows the user real-time process control enabling a number of benefits including the potential for tighter chemical tolerances, the ability to determine when alloying additions have dissolved and the ability to essentially alloy in real time without the need to take samples and wait for information back from the lab.

With some casthouses waiting up to 20 minutes to obtain their material chemical analysis results before proceeding either with further adjustment, casting or transfer, Onspec™ allows production to take control of their efficiency and give immediate results overcoming any delays. Utilising Onspec’s latest technology by taking 400 LIB samples in 2.5 minutes, the data obtained is accurate and recorded using ALTEK’s developed industrial data collection software.

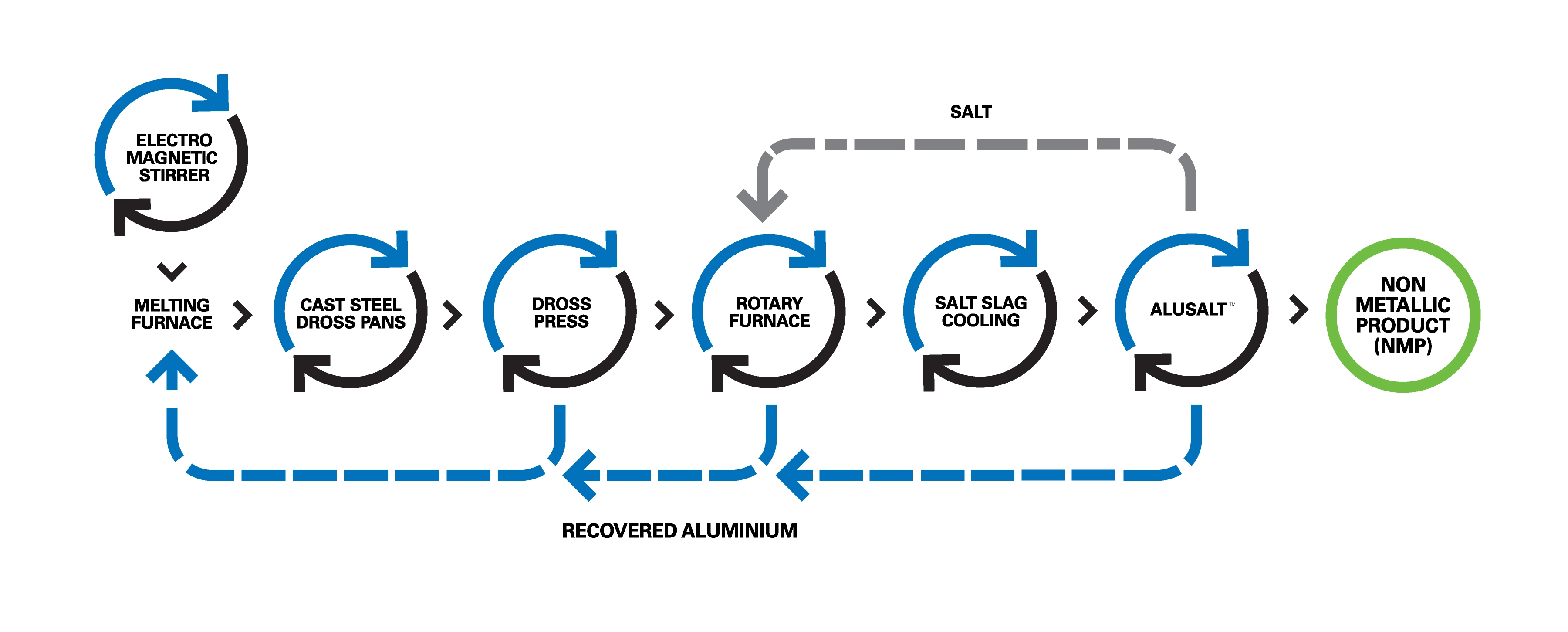

Future enhancements will include: automated accurate alloying supported by furnace bath circulation using ALTEK’s Electromagnetic Stirrer Technology, Trace elements analysis and alloy change monitoring.

- No sample preparation

- In-situ analysis

- Reduced overall cycle times

- Continual feedback on melt chemistry

- Faster response time to melt problems

- Versatile applications (furnace, launder, ladle)

- Increased operator safety

- Furnace application

- Launder application

- Real time process control

- 400 LIB samples in 2.5 minutes

- Safer operation practices

Explore new and exciting possibilities with ALTEK

Fill out the form and our sales team will reach out to start a conversation about how ALTEK can help your business save money.

For urgent enquiries, email us at altsales@harsco.com