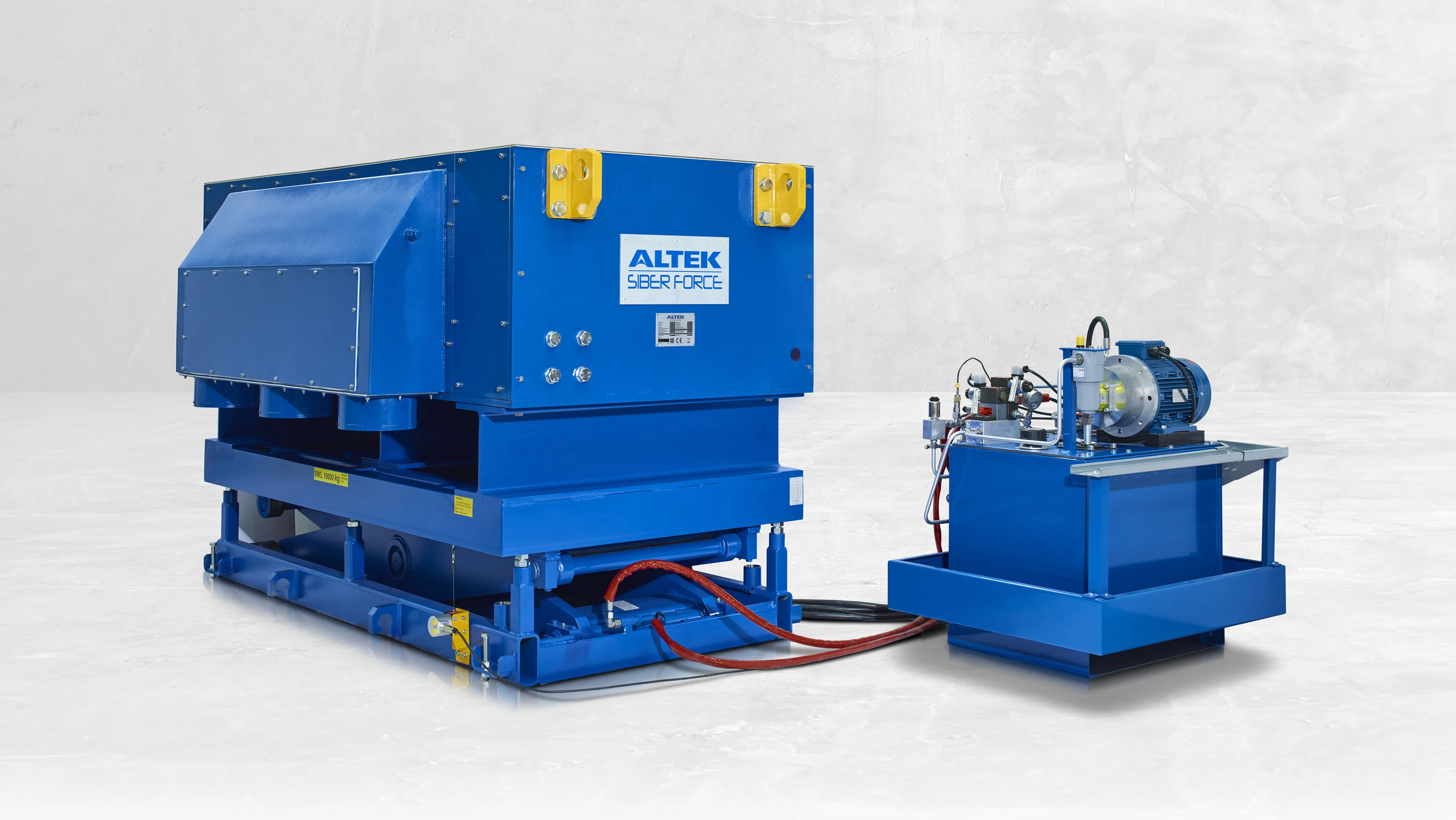

TARDIS Generation III Dross Press

Our latest technology, generating maximum recovery - Maximise Inhouse and Secondary Recovery. The ALTEK TARDIS Gen III takes the traditional dross press to a new level combining the proven robust solution with the latest in connectivity and information.

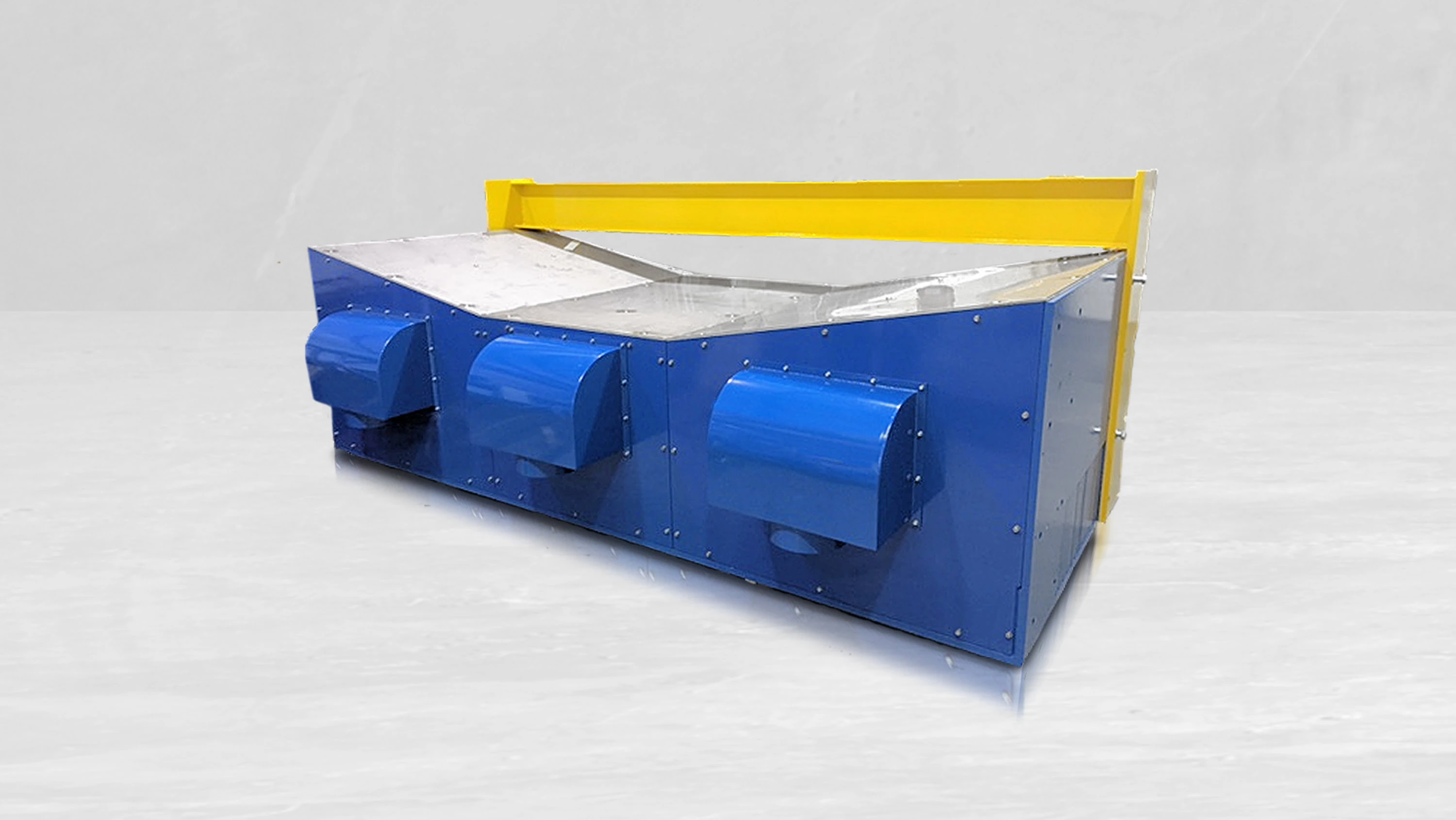

Find out moreAluminium Salt Slag Cooling Press

The ALTEK Salt Slag / Rotary Furnace Slag Cooling Press is based on the same principle as the ALTEK TARDIS Gen III technology but it has several special design features.

Find out moreRHINO-CAST® Dross Pans

RHINO-CAST® Steel Alloy Products play a vital part of a larger cost effective sustainable End-To-End Dross Management Solution that can help give a faster return on investment over a much shorter period of time.

Find out moreSalt Slag Bins

Salt slag bins supply are designed specifically to cope with the extreme heat generated from Secondary Remelt Tilt Rotary Furnace and can be used in a variety of dross press models or alternatively as a standalone salt slag cooling process.

Find out moreSow Mould & Ingot Castings

Through our experience in designing durable castings for the ALTEK Dross and Salt Slag cooling presses, ALTEK has expanded its product base and now supplies a variety of casting products for the aluminium industry.

Find out moreElectromagnetic Furnace Stirring (EMS)

The most versatile and cost-effective air-cooled electromagnetic furnace stirring system available to the aluminium industry.

Find out moreCurved Electromagnetic Stirrer (CES)

Based on their highly successful, versatile Electromagnetic Stirring (EMS) range, ALTEK have developed a curved electromagnetic stirrer design.

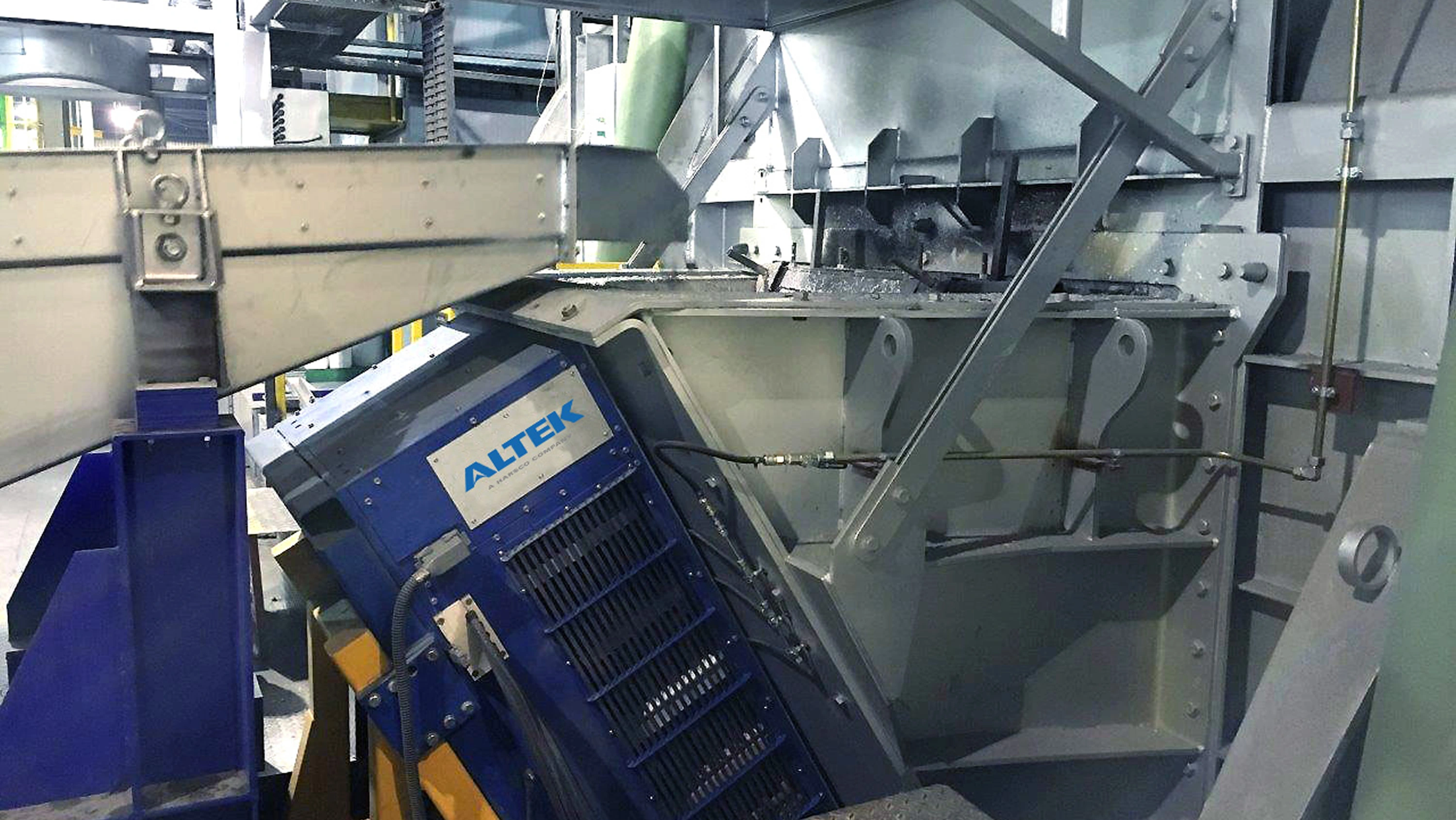

Find out moreScrap Submergence System

The Scrap Submergence system consists of an inductor mounted against an inclined charging well installed on the furnace.

Find out moreOnSpec™ Continuous Molten Metal Analysis

Metal quality is a critical and essential part of the finished product and the control of this as an integral part of the production process.

Find out moreTilting Type Rotary Furnace

Tilting Rotary Furnace Technology plays a vital part of a larger cost effective sustainable End-To-End Dross Management Solution.

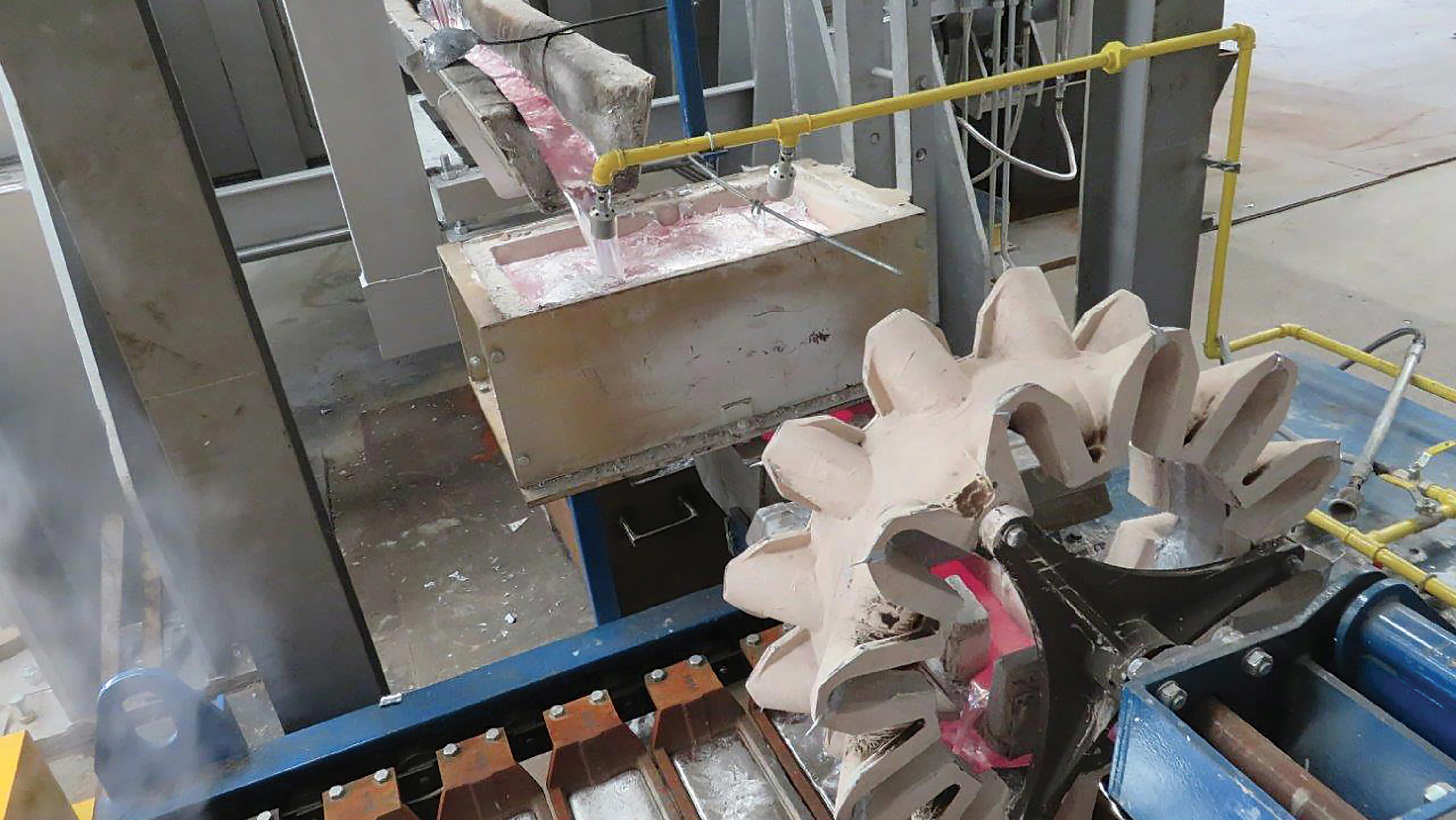

Find out moreIngot Casting Machines

ALTEK Ingot Casting Lines are used to convert liquid aluminium, typically from Tilt Rotary Furnaces or Holding Furnaces into small ingot stacks.

Find out moreAluSalt™ Salt Slag Cake Recycling

It has been proven around the world that the use of salt when operating Rotary Furnaces provides optimum control and maximum recovery of aluminium from dross and scrap.

Find out moreRAME™ Primary Dross Recycling Plant

RAME™ is a process specifically designed for primary smelters, achieving excellent yields higher than TRF with salt flux operations, is a salt free process, and has the flexibility to process all dross types.

Find out moreExplore new and exciting possibilities with ALTEK

Fill out the form and our sales team will reach out to start a conversation about how ALTEK can help your business save money.

For urgent enquiries, email us at altsales@harsco.com