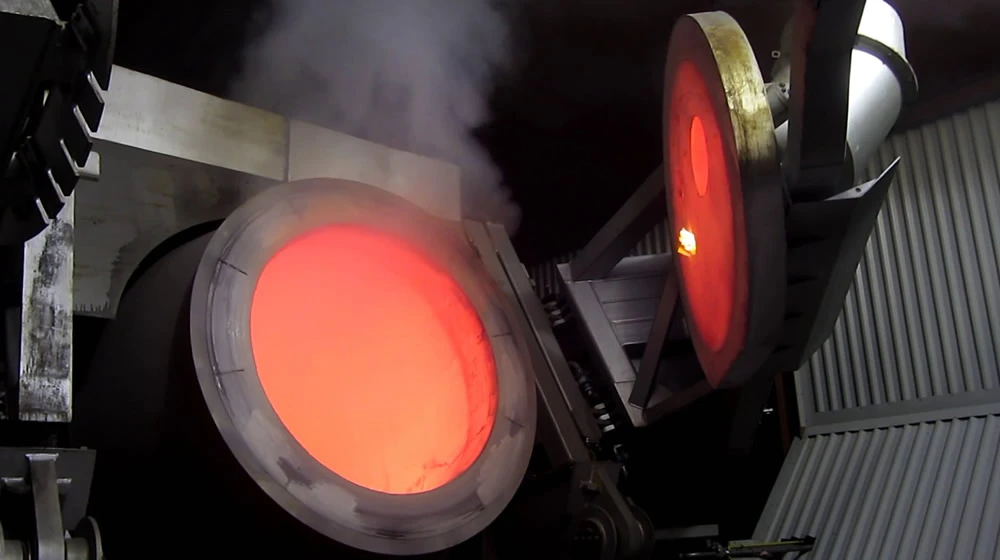

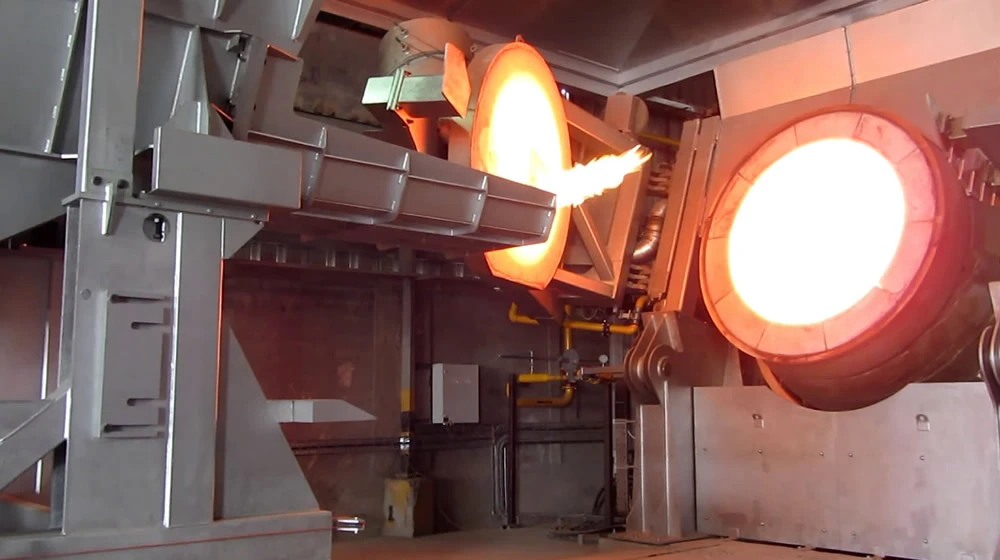

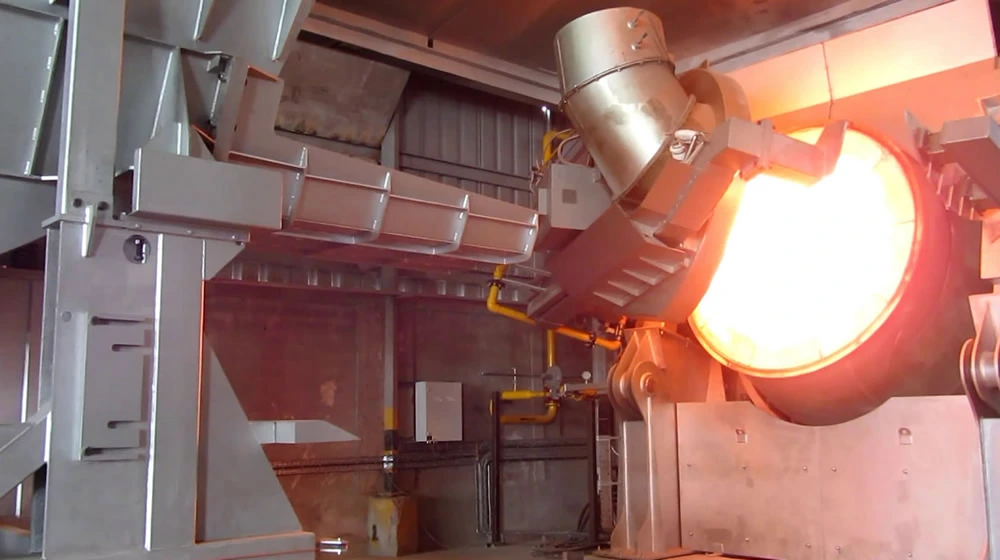

The ALTEK Tilting Type Rotary Furnace Is The Culmination Of Decades Of Development

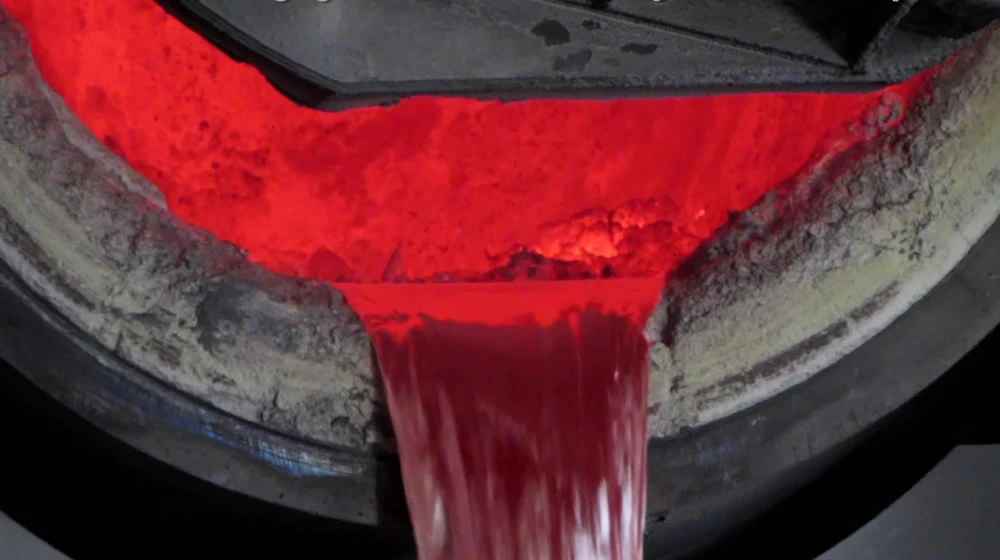

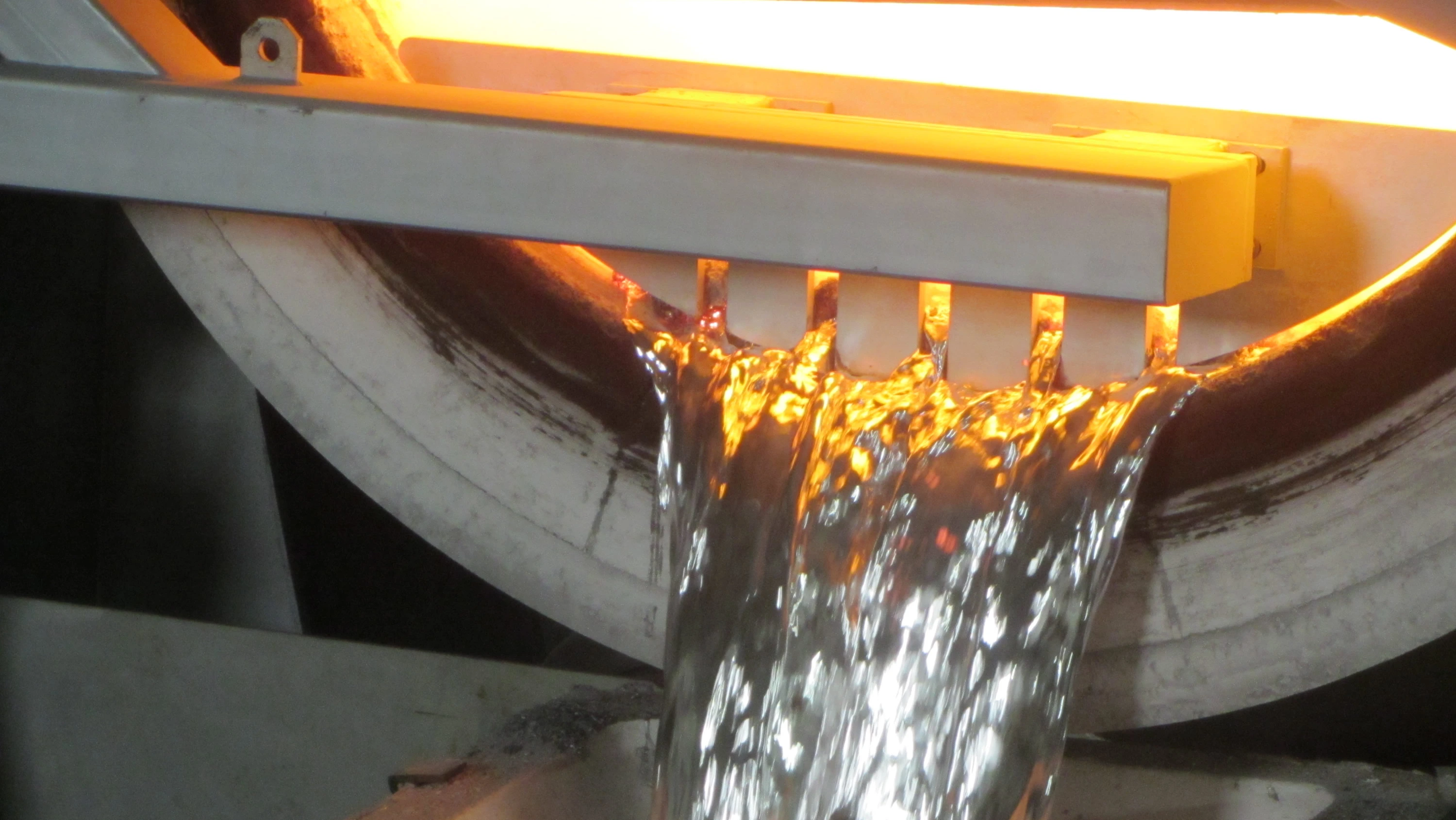

Whether you process aluminium dross, UBC, chips or iron scrap, the ALTEK Tilting Type Rotary Furnace can increase throughputs, improve metal recovery and lower overall energy consumption. With over 60 installations throughout the world, the ALTEK Tilting Type Rotary Furnace is the leading rotary furnace technology available to the aluminium industry.

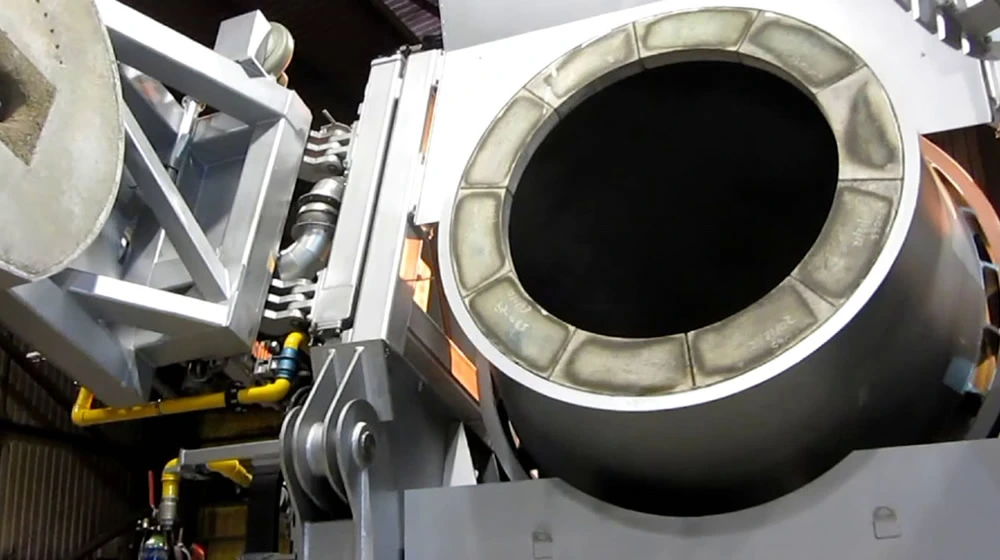

ALTEK has created the most advanced and competitive rotary furnace offering customers various patented features to aid and improve operational efficiency. All designs come with a dedicated rotation mechanism and a high efficiency fume extraction system suited to the plant requirement and layout.

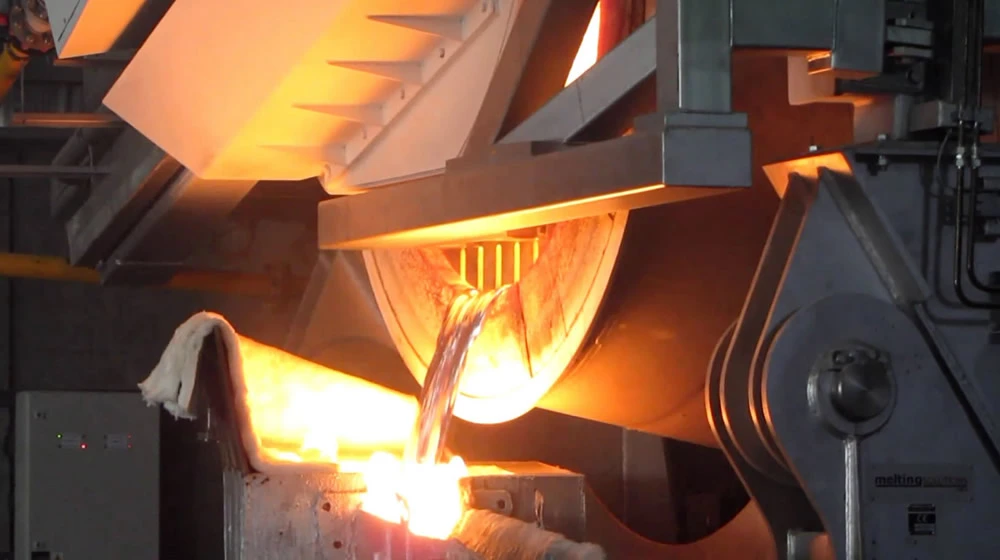

Our multi-directional door has proven to reduce energy consumption by 15%. A 20° tilt back provides less charges and quicker melt cycles. Our refractory lining is pre-cast block technology which reduces downtime. A pin-drive rotation mechanism offers the most reliable technology.

With ALTEK you are not just buying a technology, you are buying the process knowledge as well, ensuring your operators are fully trained in best practices for all scrap types. Tilting Rotary Furnace Technology plays a vital part of a larger cost effective sustainable End-To-End Dross Management Solution that can help give a faster return on investment over a much shorter period of time. Typically as little as two years.

- Maintenance friendly

- Variety of burner configurations

- 1T - 40T capacity designs

- Lowest energy consumption

- Fast and efficient

- Melt rates of all scrap types

- Operator friendly

- Process knowledge

- Best practices

- Reduced energy consumption

- Cost effective sustainability

Explore new and exciting possibilities with ALTEK

Fill out the form and our sales team will reach out to start a conversation about how ALTEK can help your business save money.

For urgent enquiries, email us at altsales@harsco.com