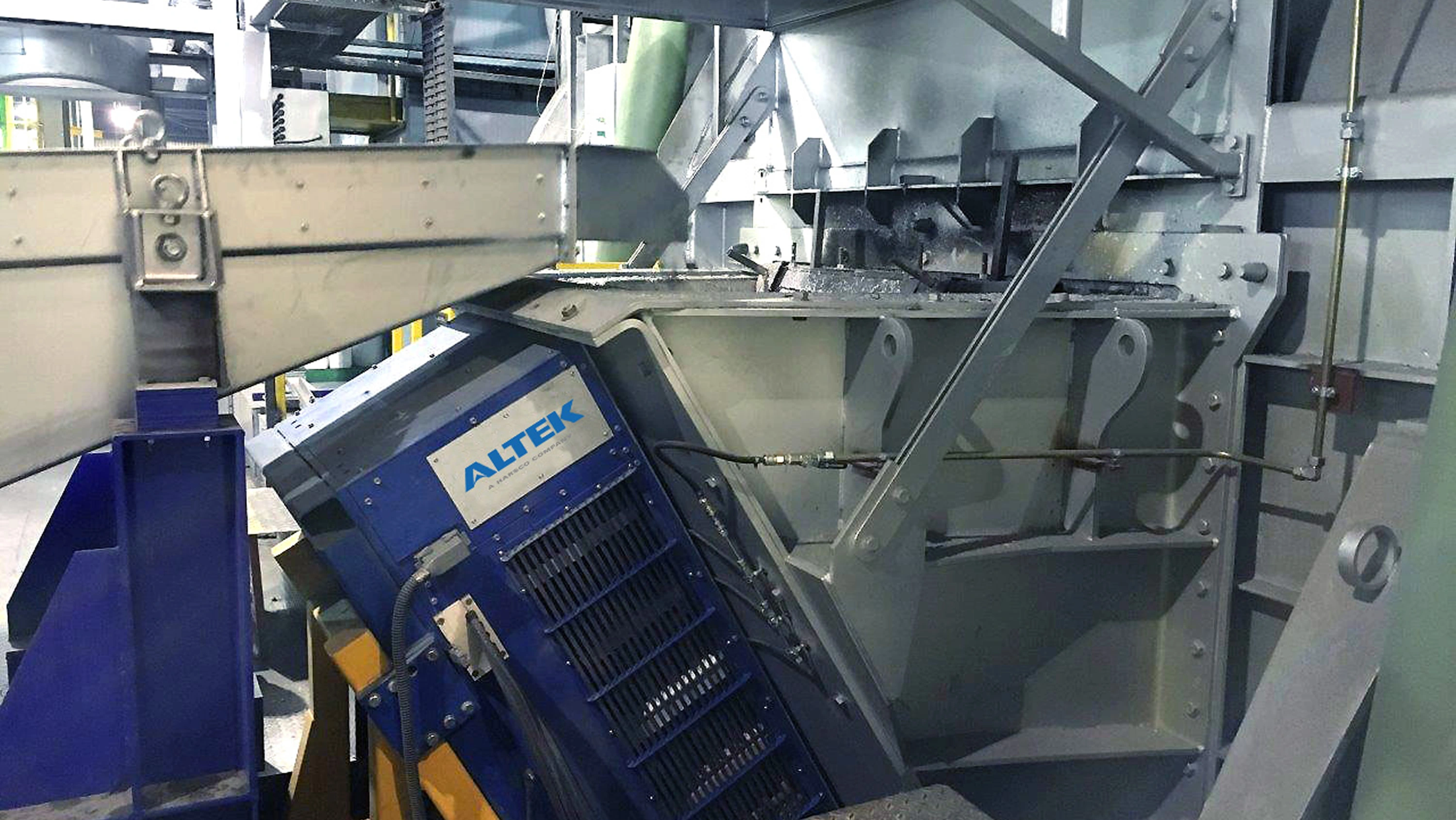

Electromagnetic Scrap/Alloy Submergence System

Utilising the industry proven ALTEK air-cooled, electromagnetic technology, this system consists of an inductor mounted against an inclined charging well installed on the furnace. The charging well contains a refractory-shape which in combination with the electromagnetic field induces metal flow, generates a quasi-vortex submerging action with minimal turbulence. The inductor operates through a stainless-steel plate and thick refractory wall of the well offering full furnace structural integrity.

The system has no moving parts, tubes, or consumables. The submerging effect ensures light gauge scrap (e.g. chips or shredded extrusion) or alloy additions can be efficiently charged, submerged, and melted away from direct flame impingement in a reduced turbulence stream of hot metal coming from and returning to the furnace. This submerging effect ensures the light gauge charge is melted with minimal burning/oxidation ensuring optimum metal recovery.

- Continuous efficient flexible charging of light gauge scrap and alloy additions

- Improved metal/alloy yield – no direct flame impingement

- Charging rates up to 5 metric tonnes/hour*

- Ease of retro fit to existing furnace, static and tilting

- Operation on either continuous or dry hearth furnace

- Furnace bath circulation

- No moving parts, tubes, or consumables

- Door closed operation – energy saving

- Operational efficiency – ease of sampling

Explore new and exciting possibilities with ALTEK

Fill out the form and our sales team will reach out to start a conversation about how ALTEK can help your business save money.

For urgent enquiries, email us at altsales@harsco.com