02 June 2025 - The Complete Dross & Scrap Recycling Solution From Altek

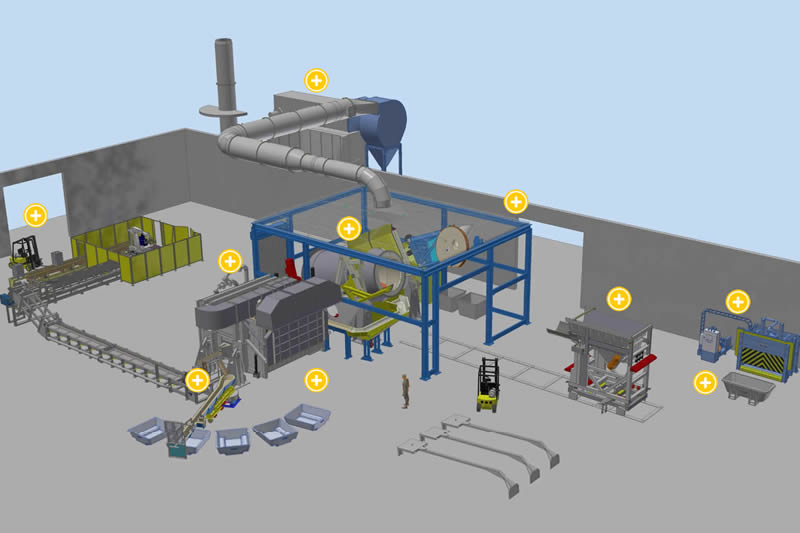

ALTEK is a technology-based company with specialist expertise and experience in the design, manufacture and installation of aluminium dross and scrap processing systems. Our engineers have many years of international experience in developing and refining solutions to dross and scrap recycling. They are a unique skill resource for our worldwide customers. Our complete dross and recycling solution encompasses eleven elements ensuring an optimum recycling process.

Tilt Rotary Furnace

Altek's TRF is extremely versatile, designed for high productivity and low energy consumption, it processes all scrap aluminium scrap types, and is also suitable for other industries such as lead, glass and other non-ferrous metal.

Fume Management Dog-House

To minimise fume filter capacity and ensure fumes are contained, Altek’s dog-house structure is designed bespoke to each project. Simpler fume hoods and structures are also available depending on customer requirements.

Filter Plant

A necessity for TRF operations, Altek work with an array of filter plant suppliers complete with lime and activated carbon dosing to meet the strictest environmental emission regulations.

Vibratory Charging Machine

Altek supplies a range of vibratory scrap charging machines of capacity and payloads, complete with weigh cells scissor lifts. Charging takes between 2 – 4 minutes depending on the scrap, and is a reliable and robust charging method.

Salt Slag Press

An adaptation of the world renowned Tardis Gen III Dross Press, salt slag is pressed, cooled and compacted quickly. Aluminium units are saved and cooled blocks can be tipped in 4-6 hours compared to 24-48 hours if left to cool naturally.

Salt Slag Bin

High quality RHINO-CAST™ steel salt slag bins built to withstand the thermal and mechanical shock experienced day to day. Internal ribs and thick walls aid in cooling times, and ensure longevity and resistance to warping.

Sow Mould Castings

Standard and bespoke models, with or without cast feet, and different cast steel alloys to choose from. Altek’s designs use thermal analysis to identify casting thickness requirements to reduce warping over time.

Sow Casting Lines

From the simplest manually operated systems, to fully continuous, fully automated systems with crucible tilting stations, Altek’s range of sow casting options suit any and all casting requirements in the industry.

Holding Furnace

Altek supply holding furnaces should chemical refinement of aluminium from the TRF cast, or casting into ingot moulds be required.

Ingot Casting Lines

State of the art, automated ingot casting lines for a range of ingot mould sizes and throughputs, complete with a range of automated marking and strapping options available.

If you wish to learn more about our wide range of cast house equipment and industry solutions please do reach out to us at altsales@harsco.com or visit us at www.altek-al.com for more information.

#Altek #Recycling #EnergyEfficiency #FurnaceStirring #Productivity #Aluminium #EnvironmentallyFriendly

Other Articles

20 February 2026

Sixth Form Work Experience Placement At Altek

18 February 2026

Altek Attend Aluminium Outlook 26 In London

17 February 2026

Happy Lunar New Year 2026 From Altek Europe

12 February 2026

Altek Winter Sports Day 2026

22 January 2026

Altek Attending IFAT 2026 In Saudi Arabia

20 January 2026

Electromagnetic Furnace Stirring (EMS) Servicing From Altek

18 December 2025

Altek Christmas Celebration

15 December 2025

Season's Greetings From Altek

11 December 2025

Altek Is Proud to Support Our Community

04 December 2025

Aluminium Dross Press Servicing From Altek

Explore new and exciting possibilities with ALTEK

Fill out the form and our sales team will reach out to start a conversation about how ALTEK can help your business save money.

For urgent enquiries, email us at altsales@harsco.com